In recent years, the construction industry has witnessed a remarkable transformation with the advent of cutting-edge technologies. Among these innovations, robotic arms and gantry 3D construction printers have emerged as game-changers, revolutionizing the way buildings and structures are created. In this blog post, we explore and compare the capabilities and impact of these groundbreaking technologies.

Robotic Arm vs Gantry Printer: Definition

Let’s start with defining the core principles of work, and how these technologies are working to understand the opportunities and differences of both machines.

A robotic arm in 3D construction printing is a specialized device designed to manipulate and deposit construction materials, such as concrete or other structural materials, in a precise and controlled manner to build 3D printed structures. It is an integral part of the 3D construction printing process and serves as the primary tool for creating architectural elements.

The 3D printing robot arm typically consists of several interconnected segments or joints that mimic the movement of a human arm.

To enable precise control and movement these segments are equipped with various:

- sensors

- motors

- actuators

The arm is mounted on a stable base or mobile platform, allowing it to navigate the construction site and reach different areas.

The end of the robotic arm is equipped with an extrusion nozzle or a similar mechanism that deposits the construction material layer by layer. The arm is programmed to follow a predetermined path, which corresponds to the digital model of the structure being printed. It precisely positions the nozzle and extrudes the material according to the design specifications, gradually building up the structure in a controlled and automated manner.

The robotic arm may also incorporate additional features such as cameras, scanners, or lasers to monitor the printing process, ensure accuracy, and make real-time adjustments if necessary. These features aid in quality control, detecting any deviations or errors during the printing process.

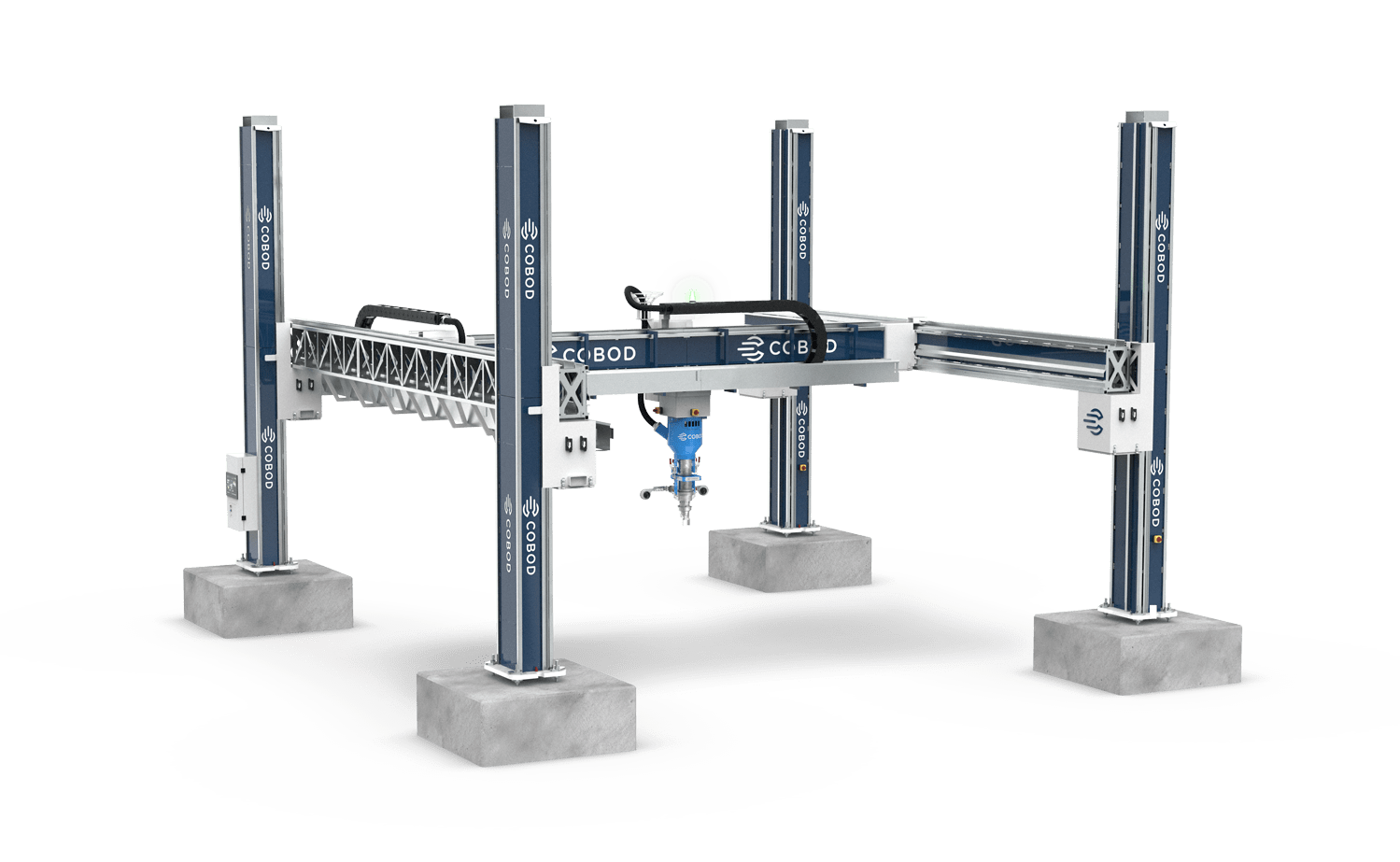

Whereas, a 3D construction printer, also known as a gantry printer, is a large-scale additive manufacturing machine specifically designed for constructing buildings and structures layer by layer. It utilizes a computer-controlled system to deposit construction materials in a precise and controlled manner, following a pre-determined digital design or model.

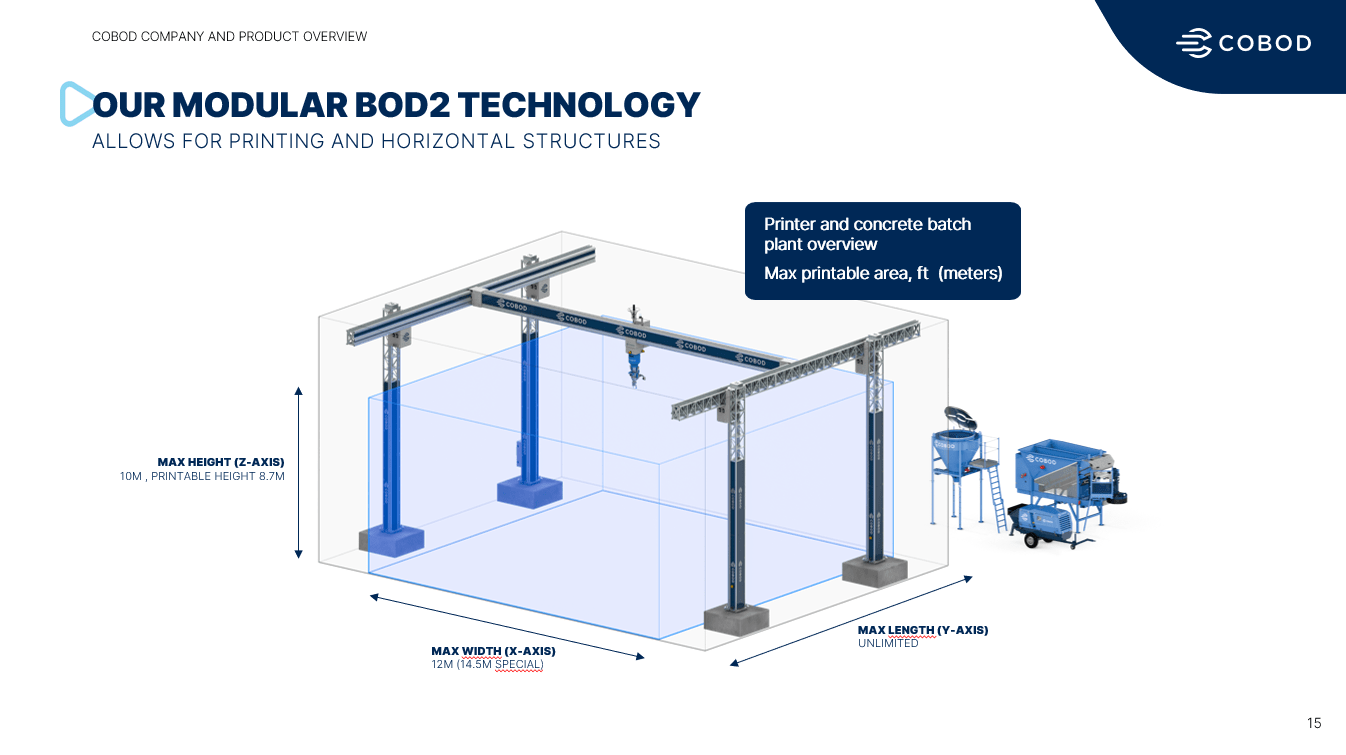

The printer typically consists of a robust gantry framework, which serves as the main structure for supporting and guiding the printing process. The gantry is equipped with multiple motors and actuators that move the printing nozzle or extrusion mechanism along the X, Y, and Z axes, allowing for precise positioning and layering of the construction material.

The construction material used in 3D printing can vary depending on the specific application and desired properties of the final structure. Common materials include concrete, cementitious mixtures, polymers, or composite materials that possess suitable strength and durability characteristics. At COBOD, we are open source regarding materials, we leave the choice up to our client. We are using a concrete solution in combination with magic D.fab admixture, developed together with the leading cement manufacturer, CEMEX.

The process begins by creating a 3D digital model of the structure using computer-aided design (CAD) software. The model is then sliced into horizontal layers, forming a set of instructions that the printer follows during the printing process. The printer’s control system interprets these instructions and coordinates the movements of the gantry and the extrusion mechanism to deposit the construction material layer by layer.

As the printer moves along the predefined path, it deposits the material in a controlled manner, gradually building up the structure. The layering process continues until the entire structure is complete. The speed and accuracy of the printer can vary depending on the size and complexity of the structure being printed and to the characteristic of deposited materials.

Comparison of 3D Printing Technologies Capabilities in Construction

In this part, we are going to explore and describe opportunities of modern construction technologies. The comparison is based on different parameters, such as printable area, material use, contingency of print, and others.

Printable Area

Robotic arm printers have shown tremendous promise in the field of 3D concrete printing. However, one of the main challenges associated with these printers is the limited printable area they offer. This limitation significantly hampers their application in testing and experimentation, making it difficult to print entire structures or buildings. Let’s dive deeper into 2 critical factors contributing to this limitation.

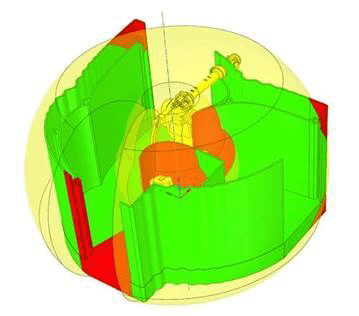

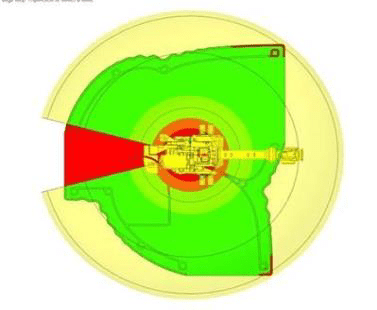

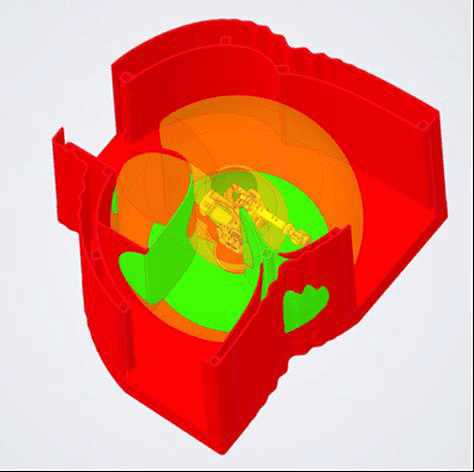

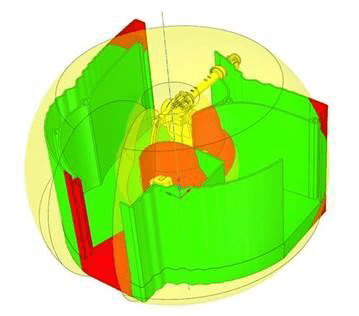

When using a robotic arm printer, the size of the arm and the need for ample space around it significantly restrict the printable area. In practice, it is not possible to achieve a 360-degree printing capability, and for most robot prints, the robot is positioned in front of the printed area, effectively printing only a “pie” corresponding to a maximum of 120 degrees. This constraint further narrows down the printable area of the robot printer. Additionally, the reach of a typical robotic arm printer, typically around 3 meters, poses limitations when attempting to print from a fixed point.

Comparing such printable area with the printing path for Europe’s first 3D printed house, The BOD, the following is evident:

The illustrated building was constructed with COBOD’s 3D concrete printing solution. We offer advanced gantry systems, which proved their efficiency all around the world. The following mind-blowing projects were implemented with our BOD2 concrete printer:

- The tallest 3D printed building in the world;

- The first 3D printed building in Europe;

- The largest 3D printed building in Europe;

- The first 3D printed medical center in the world;

- And many others.

Explore these and other 3D printed projects

As was described above, gantry printers have an XYZ axis. With our BOD2 printer it is possible to construct a building which will be up to 9 meters in height and 12 meters in width. The length of the building can vary significantly as it depends on the amount of axis you add.

Print Possibilities

In conjunction with the limited printable area, another critical consideration arises when using robotic arm printers. Specifically, the inability to construct entire buildings or structures in a single print due to the constraints mentioned earlier. As a result, users are compelled to print building elements in sections and assemble them on-site or off-site.

Off-site printing offers the advantage of operating in a controlled environment, but it necessitates the transport and subsequent assembly of the printed elements. Transport can only be undertaken once the printed elements have sufficiently hardened, usually after several days.

On-site printing eliminates the need for transport but requires on-site assembly and connection of the elements. However, on-site printing may lack the same level of control as off-site printing. Even if the robot printer is mobile, it often necessitates printing each element entirely before moving on to the next due to the curing process of the concrete. Consequently, precise timing becomes crucial when returning to the first element, which becomes increasingly challenging when dealing with multiple movements of the printer.

Moreover, the process of 3D printing elements introduces the need to establish robust connections that adhere to building codes concerning moisture and insulation. Also, other factors should be considered like aligning the printed walls and calibrating the new printable area after moving the robotic arm. While the precast concrete industry is well-acquainted with connecting elements, precast elements differ significantly from 3D printed elements. Precast elements are typically prepared with insulation and designed for easier connection, making them more suitable for connecting purposes. They also provide smoother surfaces eliminating the need for plaster work.

The power of gantry systems for construction 3D printing lies in their ability to construct large-scale structures efficiently. With their robust gantry frameworks and precise motor-driven movements, these printers can maneuver and deposit materials over vast areas, covering expansive building footprints. From residential homes to commercial complexes, the versatility of gantry printers allows for the construction of structures of various sizes and complexities. Adding the value of producing a monolithic structure as the whole building is printed in one go compared to segmenting the building as it is the case with robotic arms.

So, these large-scale printers can also print both on- and off-site, enabling constructors to create the full structures without the need of connecting separate elements or create precast elements that can be lifted and added to the existing building.

Controlling the Material Flow

A notable limitation of robotic arm printers is the absence of a print head with a hopper, resulting in continuous prints without start/stop functionality. This limitation stems from the lack of a reservoir for the materials. Consequently, the types of prints that can be achieved with a robotic arm printer are restricted, adding complexity to generating an optimal print path.

The need for continuous printing in robot printers also leads to further challenges. If the movement speed is reduced in a certain area to overcome difficulties during printing, excess material may accumulate, resulting in an uneven print or requiring manual removal of the excess. This issue is particularly noticeable when printing corners using a robotic arm printer, as the maintained material flow can lead to an excessive build-up of material in those areas.

In conclusion, while robotic arm 3D concrete printers offer exciting possibilities in the realm of construction, limitations such as:

- the restricted printable area

- the necessity for element-based printing

- the need for robust connections

- controlling material flow poses significant challenges.

Overcoming these limitations will pave the way for unlocking the full potential of large-format 3D printing in construction.

It should be noted that printing with a gantry-type printer, such as the COBOD’s BOD2 3D concrete printer, offers distinct advantages in controlling material flow through the implementation of a hopper above the printhead. Unlike robotic arm printers, the presence of a reservoir in the hopper enables the printer to pause the outflow of materials when the printhead traverses areas where printing is not required. This functionality was successfully utilized during the printing of Europe’s first 3D printed building, allowing for precise avoidance of prints at locations designated for doors and windows.

The incorporation of an auger within the hopper effectively halts the material flow through the nozzle, accumulating the materials from the pump within the hopper itself. This control over material flow proves invaluable when attempting to print structures where specific parts need to be omitted, such as when accommodating windows or other architectural features.

Read more architectural and engineering considerations in 3DCP

Although it is theoretically possible to regulate the outflow of materials from the nozzle via a ground-based pump, practical experience reveals that achieving precise control is challenging due to the dynamic nature of the material and the forces at play.

The utilization of a hopper is often not feasible with robotic arm printers. Furthermore, when hoppers are applied to robot printers, they can result in a larger and more cumbersome printhead, posing additional challenges during the preparation of the printing path. The increased size of the printhead can cause interference with previously printed areas, further complicating the printing process.

The incorporation of a hopper in gantry type printers, exemplified by the COBOD’s BOD2 3D concrete printer, provides enhanced control over material flow, enabling precise and selective printing. This feature distinguishes gantry printers from robotic arm printers, offering increased versatility and efficiency in the printing process, while minimizing potential clashes with existing prints.

Add photos of the hopper / mayne video of material flow

Brief Comparison: Robotic Arm VS Gantry 3D Construction Printer

To sum up all above, we have created the table with short and brief overview of both technologies capabilities.

| Robotic Arm | Gantry 3D Concrete Printer | |

| Definition | A specialized device designed to manipulate and deposit construction materials in a precise and controlled manner to build 3D printed structures. | A large-scale additive manufacturing machine specifically designed for constructing buildings and structures layer by layer. |

| Printable Area | Printable area is limited. effectively printing only a “pie” corresponding to a maximum of 120º. A basic reach of the arm is 3 meters max. | Gantry concrete printer can build up to 9 meters in height and 12 meters in width. The length is unlimited. |

| Print Possibilities | Can effectively print specific part of the structures and different elements. | Can print the entire buildings. |

| Material Flow | Robotic arm does not have a reservoir for the materials. This results in continuous prints without start/stop functionality. | Gantry printer has the hopper which enables the printer to pause the outflow of materials when the printhead traverses areas where printing is not required. |