The construction industry is undergoing a continuous transformation, with new technologies emerging on a regular basis. With the advent of cutting-edge construction technology, we can now build houses that are not only more efficient and sustainable, but also produced under safer conditions and at higher speeds.

In this article, we will delve into some of the most recent new construction technologies and examine how they are revolutionizing the industry.

4 New Construction Technologies Used in 2023

Innovations in the construction industry, ranging from 3D printing and artificial intelligence to green construction technologies, are having a profound impact on the way buildings are designed, constructed, and maintained.

Here is only a small part of emerging and revolutionizing new technologies in the construction industry that have been already actively implemented.

3D Construction Printing (3DCP) and Additive Manufacturing (AM)

The terms 3DCP and AM are closely associated and refer to the process of building 3D printed structures through the successive addition of layers of material until the final product is complete.

Both 3DCP and AM are used to construct entire buildings or building parts such as roofs, floors, and walls. The procedure includes developing a 3D model of the object with computer-aided design (CAD) software and translating it into instructions for the printer. The printer then produces the object by adding layer upon layer of materials such as metals, polymers, or concrete.

The impact of 3DCP and additive manufacturing on the construction industry is tremendous, since it minimizes waste, enhances efficiency, and allows for more intricate and individualized designs.

Explore more about pros and cons of 3DCP

Advanced Materials

Advanced materials in the construction industry refer to innovative materials that offer better performance, durability, sustainability, and other benefits compared to traditionally used materials. The use of advanced materials has already been implemented in high-profile construction projects such as the Burj Khalifa in Dubai and the One World Trade Center in New York City.

Examples of advanced materials used in the building sector include:

- High-performance concrete (HPC): HPC is a type of concrete that has better strength, durability, and resistance to cracking, impact, and chemicals compared to traditional concrete. HPC can also be designed to have a lower carbon footprint by using recycled materials or incorporating supplementary cementitious materials.

- Composite materials: Composite materials are made by combining two or more materials with different properties to create a material that has enhanced mechanical, thermal, or electrical properties. Examples of composite materials used in the construction industry include fiber-reinforced polymers (FRPs) and carbon fiber reinforced polymers (CFRPs) used for strengthening or retrofitting concrete or steel structures.

- Smart materials: Smart materials have the ability to sense and respond to changes in their environment. Examples of smart materials used in the construction industry include shape memory alloys (SMAs) that change their shape in response to temperature changes, self-healing materials that can repair cracks, and photovoltaic materials that generate electricity from sunlight.

According to a report by the National Institute of Standards and Technology (NIST), advanced materials have the potential to improve the performance, sustainability, and safety of buildings and infrastructure, as well as reduce their carbon footprint. They also provide opportunities for innovative and unique designs that were not possible with traditional materials. However, advanced materials may also have higher costs, require specialized expertise, and face regulatory and standardization challenges.

Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML are 2 technologies that are transforming the construction industry. AI involves the development of computer systems that can perform tasks that typically require human intelligence, such as visual perception, speech recognition, decision-making, and language translation. In contrast, ML is a subset of AI that involves the use of algorithms that allow computers to learn from data without being explicitly programmed.

In the construction industry, AI and ML are used for a wide range of applications, including:

- project management

- site safety

- quality control

- design optimization

- equipment maintenance.

These technologies have the potential to revolutionize the construction industry by increasing efficiency, reducing costs, improving safety, and enabling the creation of smarter, more sustainable buildings.

Internet of Things (IoT) and Smart Building Technologies

IoT and smart building technologies are helping the construction industry to transform drastically. IoT refers to the growing network of physical devices and sensors that are embedded in buildings, vehicles, and other objects, allowing them to communicate and exchange data with each other.

In the context of construction, IoT is used to monitor and control a wide range of building systems and processes, including lighting, heating, ventilation, security, and energy usage.

Smart building technologies, on the other hand, use IoT and other advanced technologies to create buildings that are more efficient, sustainable, and responsive to user needs. These technologies enable buildings to automatically adjust to changing conditions, optimize energy usage, and provide occupants with a more comfortable and personalized experience.

A bright example of smart building technology implication is 3D villa in the city of Riyadh, Saudi Arabia. The villa was printed with COBOD’s state-of-the-art 3D construction printer. It features smart applications that control various functions of the house, including doors, locks, AC, lighting and has 9 solar panels on the roof, which generate enough electricity to power many of the villa’s systems, including lighting and heating.

The house is an amazing example of how new construction technologies can be implemented to create a mind-blowing project.

What Are the New Green Construction Technologies?

The building sector is increasingly adopting renewable energy and green construction technologies to reduce its environmental impact. Therefore, sustainability is becoming a top priority, and new green construction technologies are emerging to help meet this goal.

In short, new green construction technologies are environmentally friendly and energy-efficient technologies that reduce the environmental impact of buildings throughout their entire lifecycle.

These solutions are designed to reduce waste, increase energy efficiency, and improve the overall sustainability of buildings. They are rapidly gaining popularity due to their ability to reduce energy consumption, minimize waste, and enhance the overall environmental sustainability of buildings.

Here are some examples of new green construction technologies:

- Solar Panels: These are devices that convert sunlight into electricity, which can be used to power buildings. They are becoming very popular due to their ability to reduce energy costs and carbon emissions.

- Wind Turbines: These are devices that generate electricity from wind energy. They are a sustainable source of energy that can be used to power buildings and reduce reliance on fossil fuels.

- Rainwater Harvesting: This is the collection and storage of rainwater for later use. It can be used for irrigation, toilet flushing, and other non-potable purposes, which helps to conserve water resources.

- Smart Home Systems: These are technologies that help to automate and optimize building systems, such as heating, ventilation, and air conditioning (HVAC), lighting, and appliances. They can reduce energy consumption by adjusting settings based on occupancy, weather conditions, and other factors.

- Green Roofs: These are roofs that are covered with vegetation, which helps to reduce energy consumption by providing insulation, as well as filtering pollutants from the air.

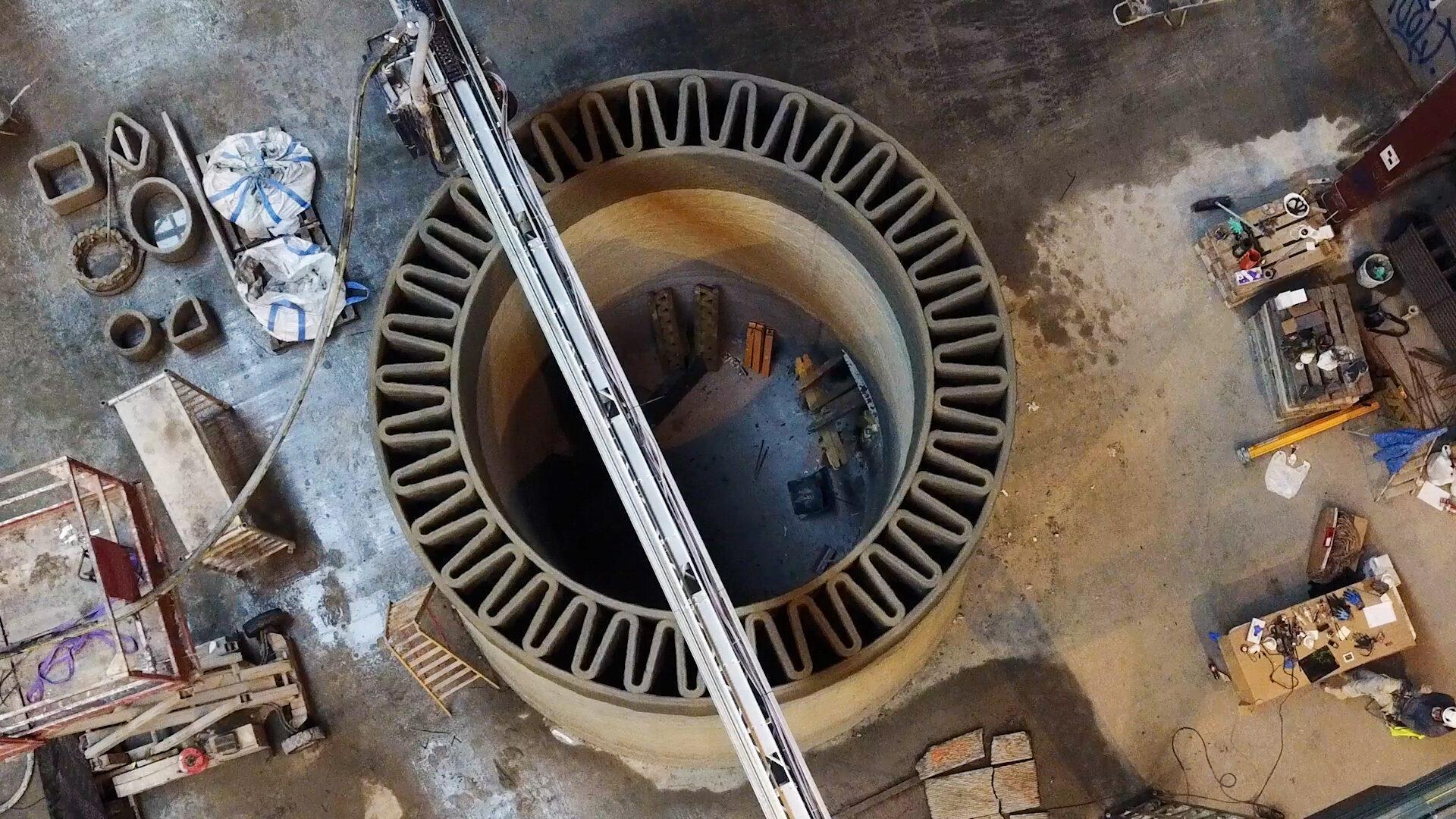

For instance, you can see below the 3D printed wind mill bases. This 10 meter structure was implemented by GE. The company did the 3D printed wind mill bases with COBOD’s state-of-the-art 3D concrete printer. Just look at these amazing forms!

COBOD is Actively Implementing New Construction Technologies

The construction industry is changing, and it’s only getting started. As new technological innovations are developed, we will likely see more applications in the industry as a whole. This will make all types of construction projects safer and more efficient, as well as easier to execute.

It is important to keep a finger on the pulse of construction innovation and new technologies. By doing so, you’re prepared to adapt your workflow and processes to meet the demands of a rapidly-evolving industry.

Each of these methods and systems have their own strengths and weaknesses that a construction project will need to consider carefully before deciding how to implement them into their particular process.

At COBOD, we are at the forefront of a new wave of construction technology that is revolutionizing the way buildings are designed and constructed. By using 3D construction printing, we dramatically reduce construction time and costs, while also improving the accuracy and precision of the final product.

D.fab – a Result of Implementing New Construction Technologies

At COBOD, we constantly explore new technologies and materials to further enhance their 3D printing capabilities. D.fab concrete solution is the best testament of our words. As the material used in 3D Construction Printing is crucial, and at COBOD, we have dedicated significant effort and time to refining our printing solution.

CEMEX and COBOD’s close collaboration, experience, and expertise have developed a cutting-edge material processing system for 3D concrete printing, known as D.fab. The solution is universally applicable, economically viable, and industrialized making it an innovative and efficient solution for 3D concrete printing.

The use of the D.fab concrete solution in 3D construction printing marks a significant advancement in the field and paves the way for effective commercialization of the technology, representing a concrete revolution in the industry.

This innovative solution enables COBOD’s customers to obtain 99% of the 3D printing concrete material from local sources, resulting in unprecedented cost-savings of up to 90%. The 3D printing material is made up of only 1% Magic Mix, engineered by CEMEX and supplied by COBOD.

Overall, COBOD is pushing the boundaries of what is possible in construction technology. By embracing new technologies and materials, we are helping to create a more sustainable and efficient future for the construction industry.