- The world’s first on-site 3D printed large water tanks have been constructed in Kuwait by Abyan using a COBOD 3D construction printer and achieving a 25% savings on the amount of concrete and reinforcement used compared to casted tanks.

- Benefitting from the speed and design freedom of 3D construction printing the tanks can be made faster, more economical, and sustainable than when using traditional formwork.

- The tanks with 4,5m in height and a diameter of 7m were 3D printed with low cost concrete in just 5 days and only contained macro fibers for the reinforcement of the tank walls and no traditional reinforcement meshes.

- The end customer was very pleased with the fast delivery and wants to have more 3D printed tanks in the future.

The design freedom of 3D construction printing has been known for years and has mostly been used for the creation of aesthetically more interesting and appealing buildings. However, design freedom also provides huge benefits for structural engineering and sustainability.

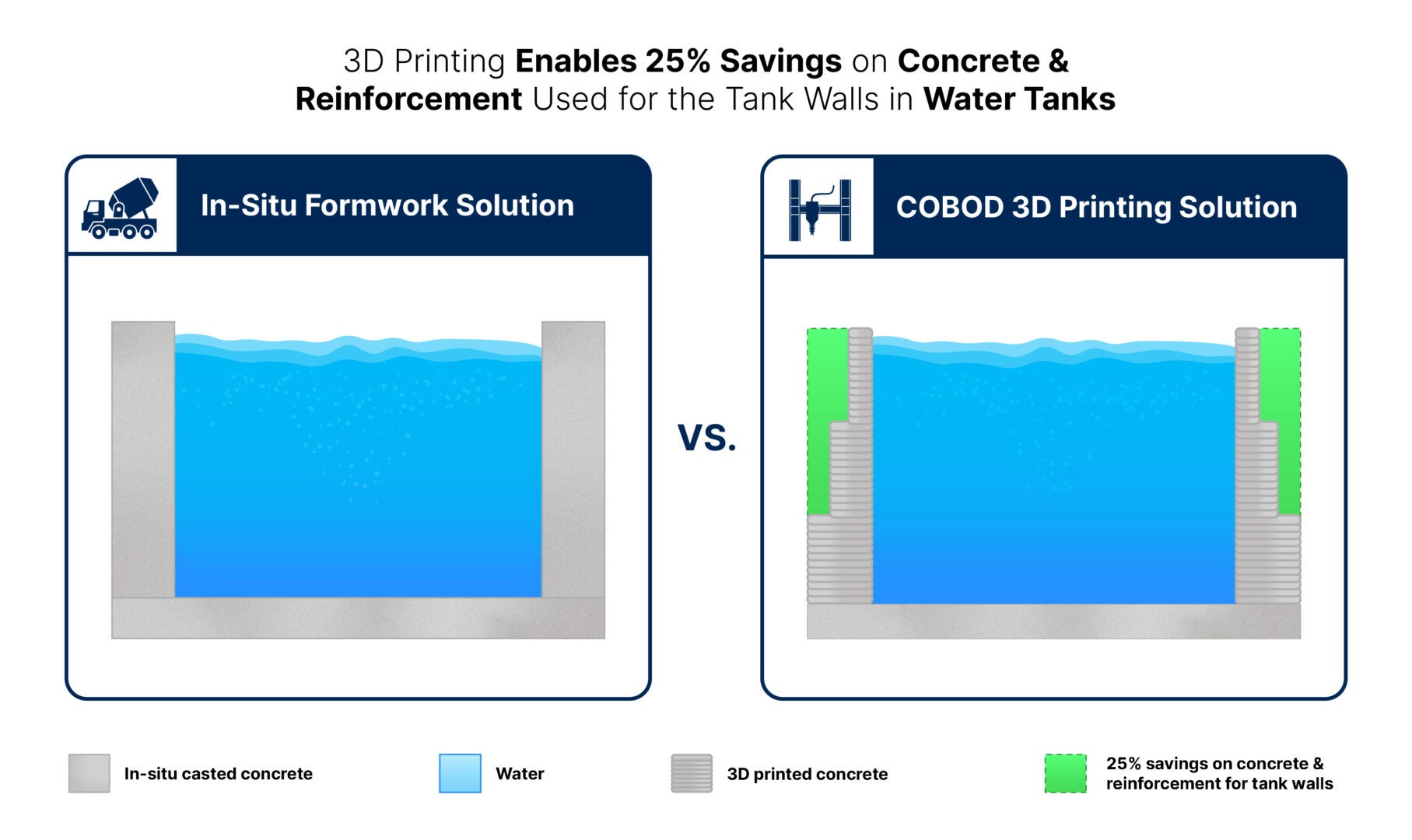

When constructing large tanks with the traditional method of formwork and concrete, the tank walls must be the same thickness from top to bottom because formwork can not vary the thickness in height. 3D construction printing does not have this limitation, allowing structural engineers to adjust the wall thickness where needed. Since gravity and water pressure make the bottom of the tank experience more stress, those areas need thicker walls. With 3D printing, the bottom walls can be made thicker and the upper walls thinner, saving materials and making the construction of the tanks both more economical and sustainable.

This structural engineering principle is reflected in the below diagram, showing that the tank in Kuwait had 40cm wall thickness at the bottom part, 30cm in the middle part, and 20cm at the top part, leading to 25% less concrete and reinforcement have been used for the walls, compared to if the tank had been cast with 40cm walls all the way up.

The tanks were printed with a low-cost real C40/50 concrete mixed on-site using the D.fab solution and related printing equipment invented by CEMEX and COBOD, where 99% of all raw materials used are locally sourced. To further increase the speed of execution, Abyan insisted on using macro fibers for the reinforcement of the concrete. Macro fibers have not been used for reinforcement of 3D printed real-life structural constructions before, so the requirements from Abyan presented a real challenge. Henrik Lund-Nielsen, Founder & General Manager of COBOD said: “Abyan pursues real innovations, which we really want to support and they wanted to try to avoid using any hard reinforcement in the walls, and just add fibers to the concrete. Of course, this challenged us a lot, but together with Cemex, the three of us were able to find a very good solution, which now can be replicated elsewhere in the future”.

Abyan’s willingness to be innovative and try out new solutions is a consequence of the scientific background of the CEO and co-founder of Abyan, Dr. Ahmad Al-Nassem, who is a professor of structural engineering at Kuwait University. Dr. Ahmad Al-Nassem said: “It is in the DNA of Abyan to be innovative. Abyan is wholeheartedly committed to revolutionizing the construction industry at large by integrating cutting-edge 3D printing technology within concrete construction along with innovative solutions in design and construction materials, bringing forth a new era of efficiency and sustainability. So, when all of our calculations showed that with 0,95% macro fibers in the concrete, we could remove all hard reinforcement of the tank walls, we were keen to prove this new design concept with a real-life project”.

The two tanks were printed for Kuwait United Poultry Company and will be used for chicken drinking water at one of their many chicken farms in Kuwait. Due to the cost and time savings realized in the project, Kuwait United Poultry Company is keen to continue 3D constructing printing for tanks in the future. Mr. Muhammad Al-Hussain said: “We are very happy about the results of this project and for the huge savings in time. We will surely repeat this method in the future and get more 3D printed tanks for our many chicken farms”.

ABOUT COBOD INTERNATIONAL

We are the world leader in 3D construction printing solutions with +65 printers sold worldwide.

COBOD’s mission is to build smarter through multifunctional construction robots based on 3D printing technology and COBOD’s vision is to automate a minimum of 50% of construction processes on building sites. All leading to better, faster, cheaper, and more sustainable construction than conventional concrete. We constantly strive to reduce the CO2 footprint of 3D printed concrete.

COBOD’s 3D printers made Europe’s first building in 2017. Subsequently, our printers made the first 2- and 3-story buildings in Europe (Belgium & Germany), North America (US & Canada), and India. Also, the first 3D printed villa in Dubai and buildings in Africa have been done by COBOD 3D construction printers, just like the first wind turbine bases.

COBOD has an open-source material strategy, partnering with customers, academic institutions, and suppliers around the world.

COBOD is privately owned by General Electric, CEMEX, Holcim, and PERI as key shareholders, and our partners further include Dar Al Arkan (Saudi Arabia), L&T Construction (India), JGC (Japan), Siam Cement (Thailand) and Orascom (Egypt).

COBOD is headquartered in Denmark with regional offices and competence centers in Florida and Malaysia. Our team consists of +100 passionate pioneers from 25 nationalities and through our installed base of printers, we have a truly global presence in North- and Latin America, Europe, the Middle East, Africa, and Asia-Pacific.

ABOUT ABYAN

Abyan Building Construction Company was founded in 2022 as a trailblazer in the construction sector, leveraging state-of-the-art concrete 3D printing technology. This innovative approach to construction allows for precision and efficiency in building processes for load-bearing structures like water tanks and construction structures and much more. Abyan is committed to revolutionizing the construction industry not only in Kuwait,but in the GCC market at large by integrating cutting-edge 3D printing technology within concrete construction along with innovative solutions in design and construction materials, bringing forth a new era of efficiency and sustainability.