- In an unprecedented showcase PERI took it upon themselves to live 3D print the walls of a small house each day for 7 days at the Bauma exhibition last week in Munich, Germany the largest construction exhibition in the world

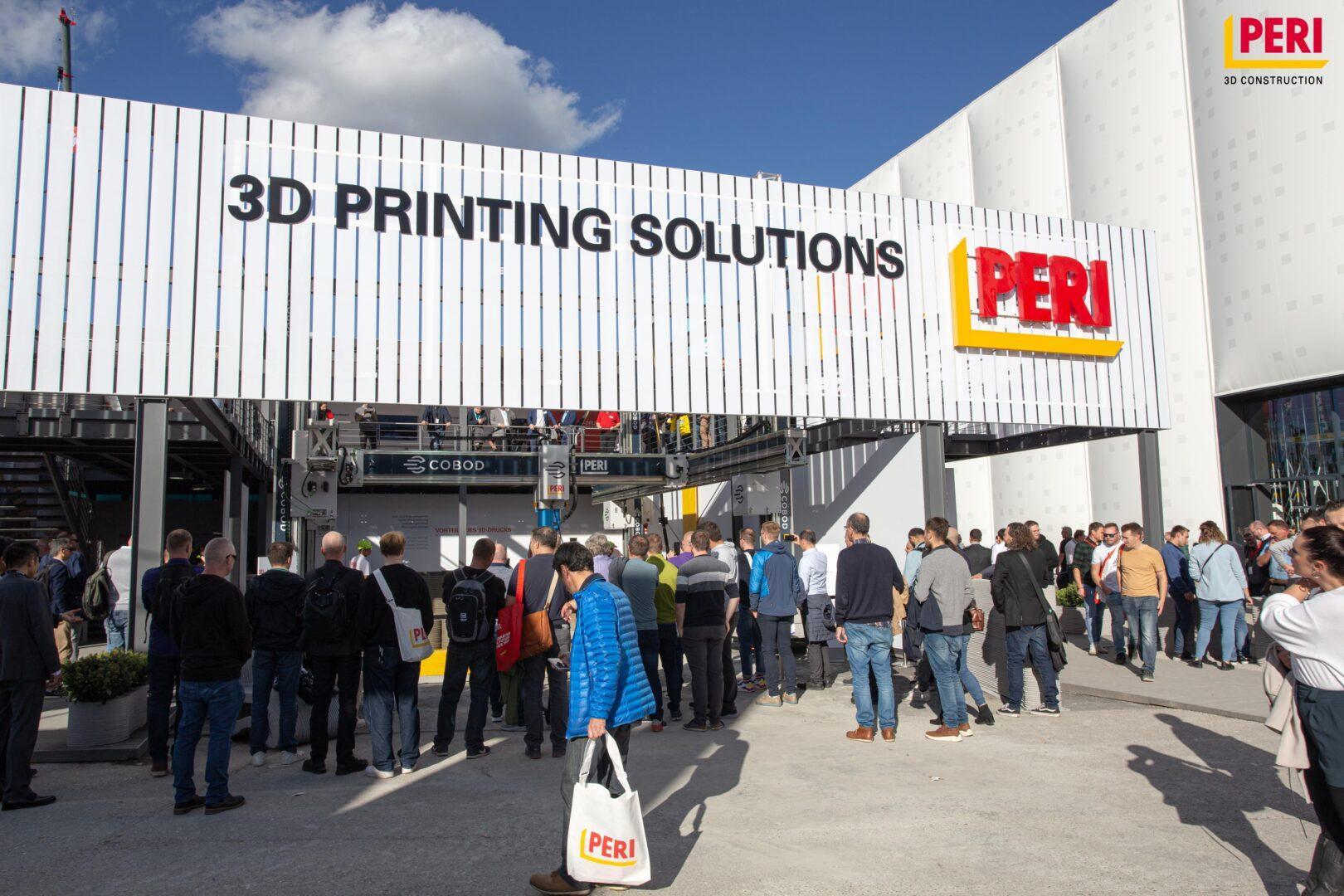

- More than 600,000 visitors from 200 countries attended the exhibition, with over 300,000 coming to the PERI stand

- Spectators crowded to see the live 3D printing, which constantly had an audience from around 50 to over 300

- The printing occurred outside without the use of a tent and continued even during periods of rain

Each day visitors crowded the PERI stand to see the BOD2 3D construction printer create the walls of a small house, a remarkable demonstration of the technology’s readiness for the market.

While other companies involved in 3D construction printing might also be participating in construction exhibitions, very few providers actually showed up with a large 3D construction printer for the visitors to see, and no one has ever demonstrated live 3D construction printing to as many people as PERI and COBOD did during Bauma. The live printing was the talk of the town attracting more than 300 people to the stand at the same time.

PERI is distributing printers from COBOD in several European countries and the US, and is behind many of the most known 3D printed buildings in the world, including the first 3D printed 3 story apartment building in Germany and the first two story 3D building in Houston, US.

Fabian Meyer-Brötz, CEO of PERI 3D printing commented: “During Bauma we proved in front of all the thousands of visitors, that we with a minimal crew each day could 3D print the walls of a small house. We are not aware of any other technology, which can produce such results. We even continued printing during the many rainy periods during the exhibition without using a tent to cover the printer”.

The BOD2 printer from COBOD is the world’s best-selling 3D construction printer. COBOD has sold more than 50 of them on a global scale, and COBOD’s printers can be found on all industrialized continents. The BOD2 has a modular build and can be extended in any direction with modules of 2,5 meter, to a maximum of 15 meters in the width and 10 meters in the height. In the length the printer can be as long as desired. For Bauma PERI brought a relatively small BOD2 printer measuring 7,5m*10m*5m.

Henrik Lund-Nielsen, Founder & General Manager of COBOD explained: “At this Bauma PERI has proved, that our BOD2 printer technology has the quality, speed, robustness, and stability to perform hour after hour, day after day and with incredible productivity beating the conventional construction methods. With our technology our customers will be significantly more productive than users of conventional construction equipment and methods”.

Besides demonstrating the market readiness of the technology, the speed and limited labor force needed when printing was part of the purpose of bringing the printer to Bauma and was to prove, that 3D construction printing can happen outside even without the use of a tent, also when it is raining. So PERI did not put up a tent to cover the printer at Bauma, while the visitors was protected from the rain by a cover. This was done deliberately.

Fabian Meyer-Brötz, CEO of PERI 3D printing explained: “Many potential customers wrongly believe that a tent will always be required for 3D construction printing. By continuing to print even during rainy periods, we wanted to prove that this is not the case. Yes, in some cases a tent is the most effective solution for instance during periods with extensive rainfalls, but in most situations, there is no need for it.”