3D construction printing (3DCP) is a relatively different construction method compared to conventional methods. However, the role and skills of architects and electrical and structural engineers are still crucial for successfully implementing the project. Learn more about this in our brief introduction of architecture and engineering in 3D construction printing.

How different is the work of an architect in 3DCP?

As in the traditional construction method, the preparation and design of buildings, the so-called design phase, plays a very important role. An architect should implement a comprehensive design approach for 3D printing architecture. He or she should be sure that everything is incorporated into the model made for the printer.

As Zaid Marmash, a leading architect in COBOD, said in his interview to Architectures Cree: “The role of the architect remains essentially the same, whether it is a “classic” project or a 3D printing project. What changes is the design freedom offered by technology: “out of the box” geometries, which were not feasible with conventional methods, are now feasible and can still function as a structure system. However, the architect must acquire new knowledge about 3D printing. Because what is drawn on the computer is what is printed.”

Design Phase in 3DCP

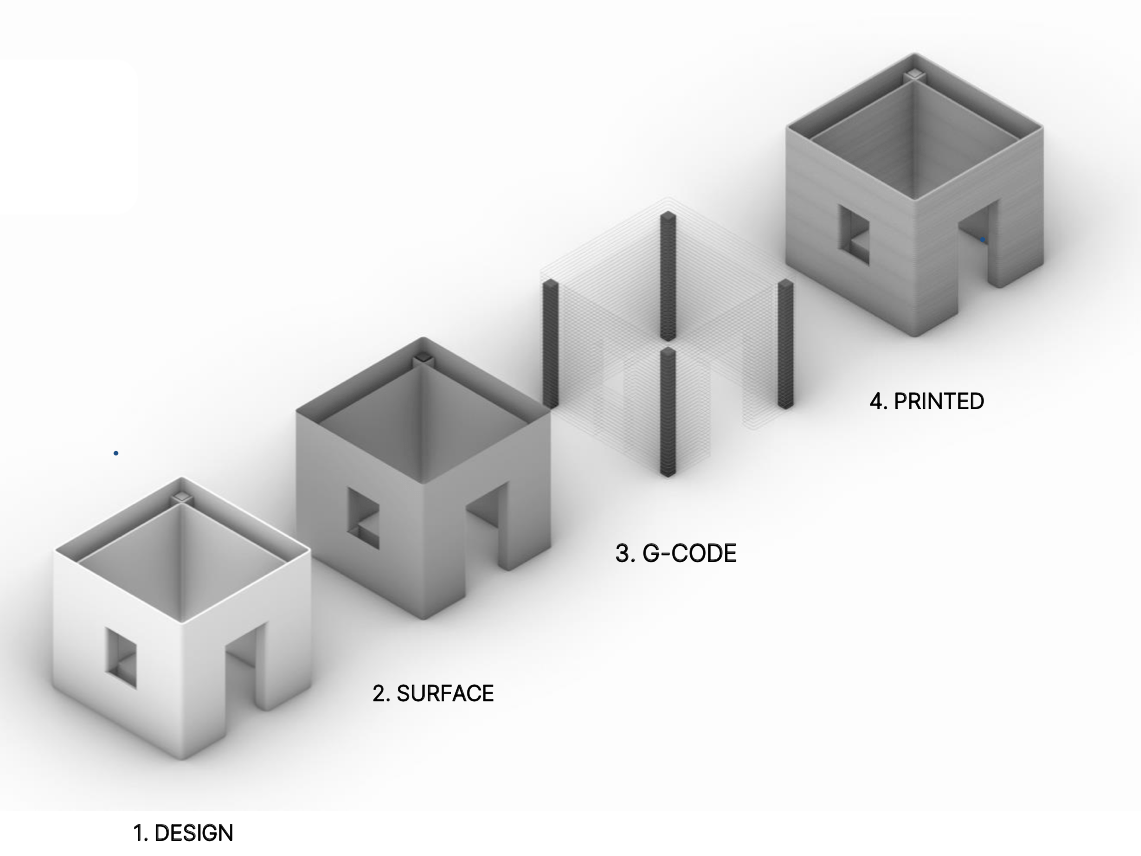

The structure can be created using traditional techniques, ideally taking into account the limitations that the construction method (3DCP) offers. An architect makes sure that each planned wall edge is offset inwards while modeling the surfaces in the appropriate CAD program.

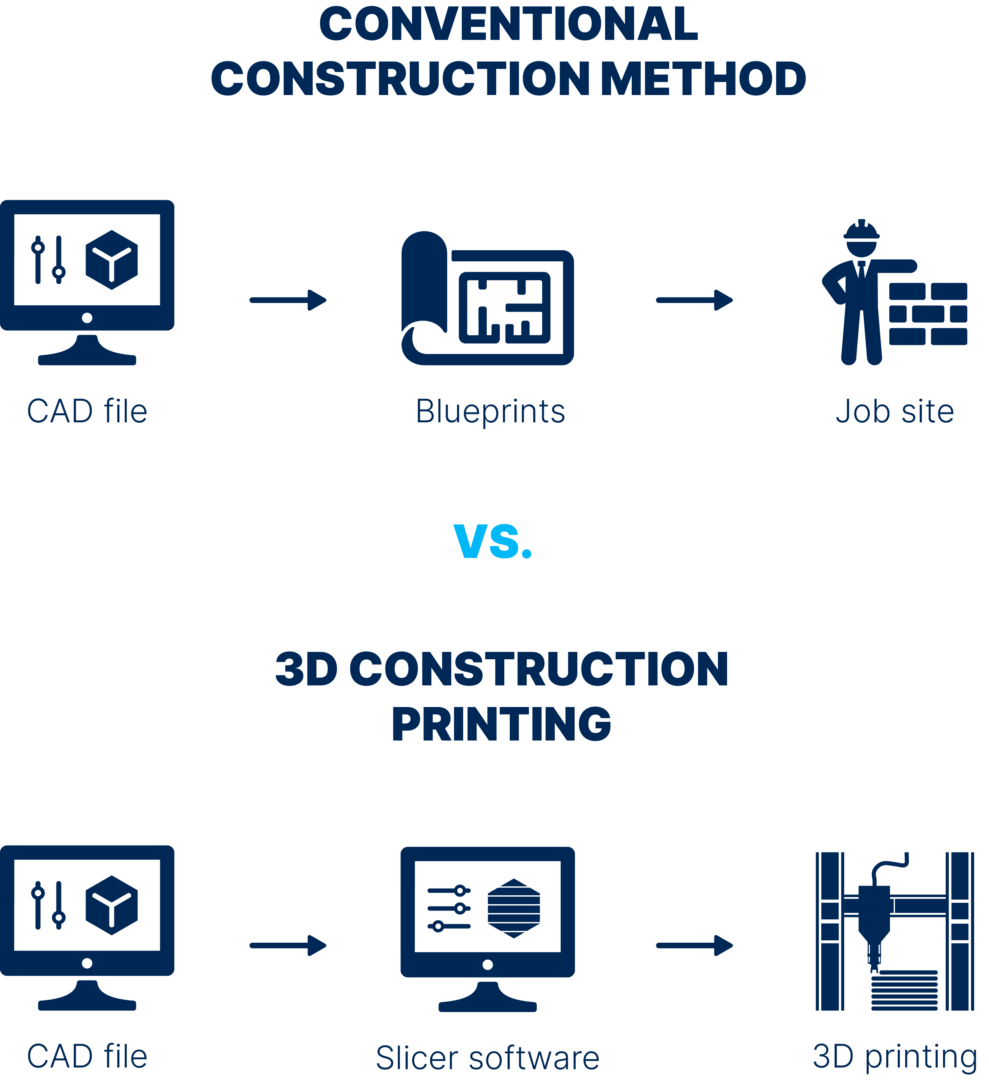

The conventional approach to building construction is prevalent and often considered the standard practice for designing and erecting structures. In this process, Computer-Aided Design (CAD) programs are utilized to produce drawings and blueprints, which are then used by builders and on-site personnel to construct the desired design in accordance with the specifications and instructions provided by architects and engineers.

In contrast, 3D construction printing technology involves the use of CAD files to directly print or construct the building. As a result, additional considerations are necessary when employing this method. Before the CAD files can be converted into a code that the printers can understand and execute, certain steps must be taken.

At COBOD, we provide our customers with a specific application to convert CAD files. This is called COBOD Slicer and is a proprietary software developed by COBOD This app transforms models and basically “slices” them. Then it is possible to slice a surface into separate horizontal levels that serve as toolpaths for the 3D printer to deposit material layer by layer.

Moreover, during the design phase, architects can cooperate with structural engineers to design the walls of the future construction. Nevertheless, the design options for the walls using 3D concrete printing are nearly unlimited, there are several consideration points.

Factors to take into account when designing the 3D printed walls:

- Wall type (load bearing / non-load bearing)

- Wall thickness

- Insulation type and local requirements

- Avoiding thermal bridges if necessary (depending on local building code)

- Layer height

- Layer width

What is the Role of Engineers in 3D Construction Printing?

As with architects, the work of electrical and mechanical engineers in 3D construction printing does not differ significantly during the design phase from traditional methods. Engineers still plan wiring, water supply, ventilation, HVAC and so on during phase design.

However, there are significant differences during the implementation process.

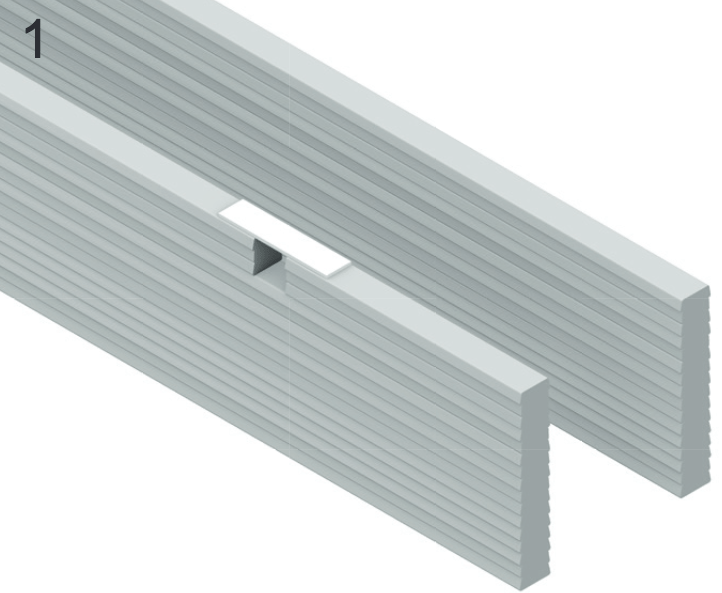

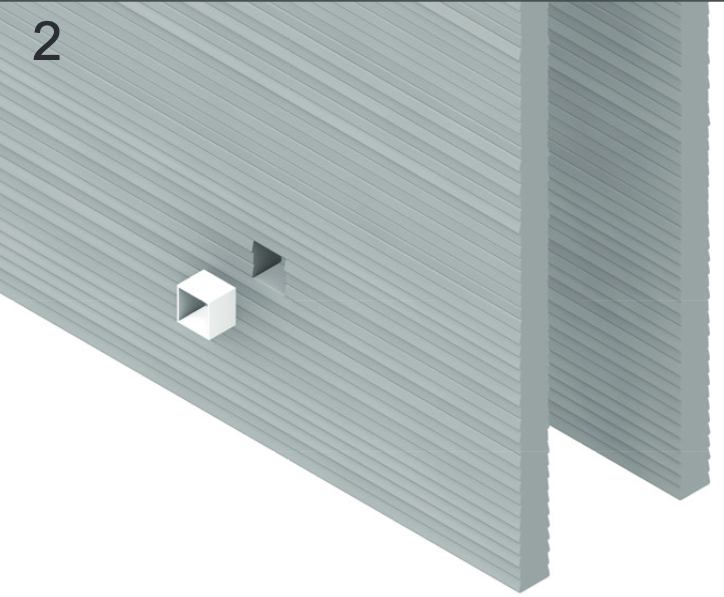

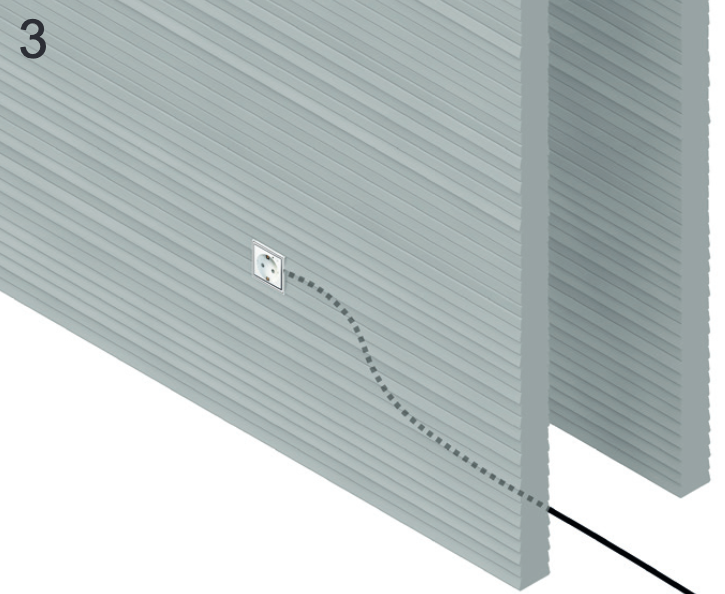

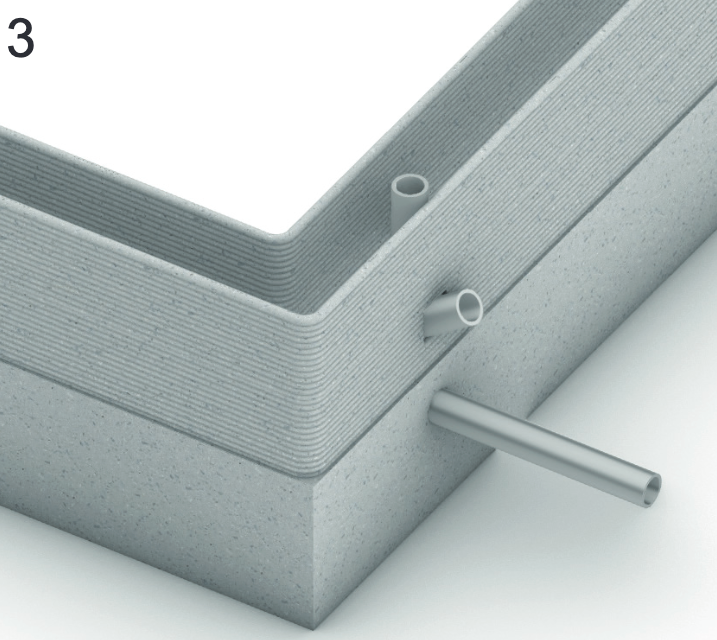

For instance, electrical engineers include the necessary voids for electrical outlets also and prepare them in the CAD file to facilitate their installation. When a 3D construction printer lays concrete or mortar layer by layer, the machine leaves room for future wiring. As a result, there is no need to drill or cut holes in the 3D printed walls to accommodate different installations.

If the walls are constructed as double walls, the wires can be installed inside both the interior and outside walls. The same technique may be used for other applications including HVAC.

Thus, by reducing additional work after the construction of walls, we reaffirm that 3DCP technology can reduce construction costs. In this case, it is a reduction in time, but more importantly, a reduction in waste and errors as it provides accuracy.

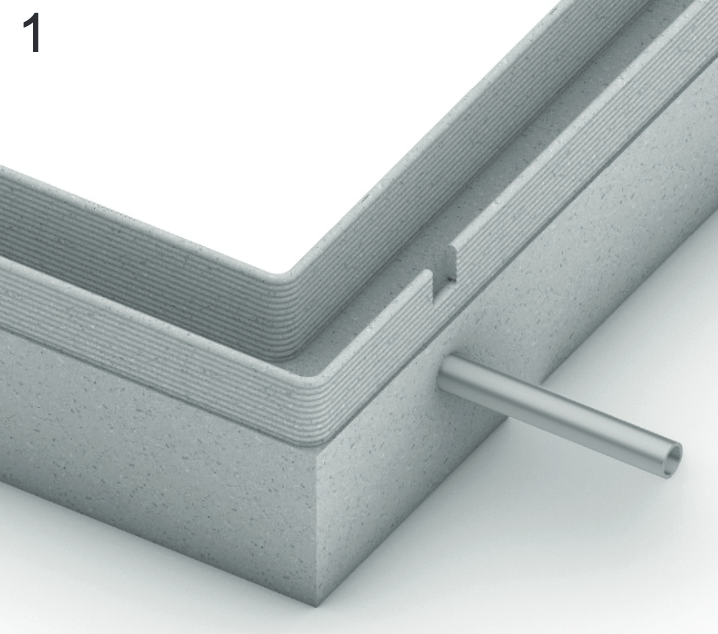

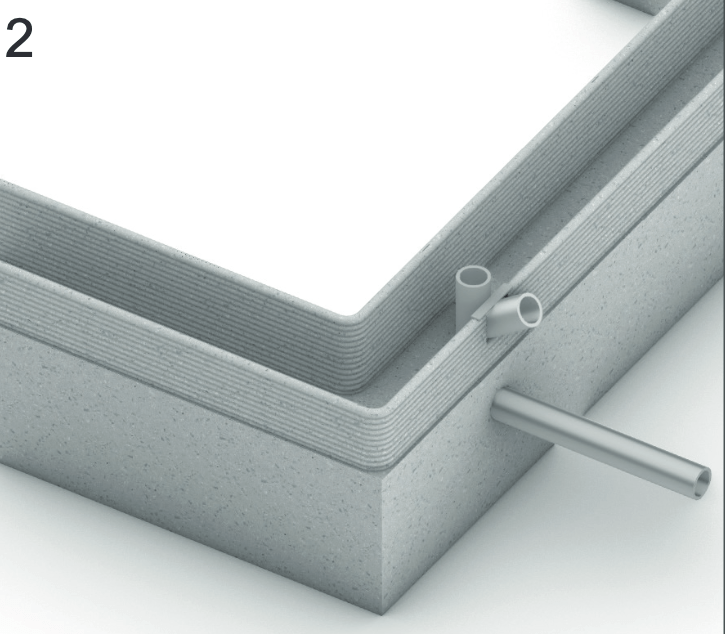

Also, as another proof of less after work is required, the primary plumbing work would be completed while working on the foundation. It is possible to install the complete water pipe system prior to pouring the foundation. Similar to wiring, engineers can install pipes in the space between the twin walls. To save drilling or cutting holes in the 3D printed walls, openings for water outputs, cleanouts, and valves can be incorporated and designed in the CAD file.

There are further choices available like placing the pipes and wiring beneath the roof or slab and covering them with an artificial ceiling afterwards.

What Role will Engineering Play in Future 3D Construction Printing Projects?

3D printing technology can assist architects, engineers, and construction workers by speeding up the design, planning, and construction process. The interest of engineers in 3D construction printing is growing considerably.

Engineers can play a key role by utilizing their traditional skills and knowledge when designing 3D construction files. Moreover, specialists can gain knowledge from learning and enhancing the process of 3D printing.

As 3D construction printing technology becomes more advanced and accessible, more engineers will be needed to provide planning and implementation services. However, it seems clear that 3D printing will revolutionize the field of architecture, in the sense that architects will be able to design and construct buildings free from traditional techniques and constraints. Though 3DCP technology is still relatively new, more engineers will use it to aid in the building of structures and homes over time.