3D Construction Printing, in short, 3DCP, can innovate construction and bring about a positive change. But what is it, how does it work, and what are the advantages?

3D construction printing expands on the familiar concept of the plastic 3D printer but on a much larger scale. This technology is a form of additive manufacturing where material is added layer by layer. In 3D construction printing, the typical material used is mortar. However, some printers also accommodate printing with concrete, which offers greater durability and structural integrity compared to mortar. Key to the technology is a 3D construction printer linked to a material delivery system. This unique system enables a steady supply of material to the printhead, where it gets extruded through a nozzle. The printing process is highly automated, guided by predefined settings within specialized software tailored for 3D construction. This automated process not only makes construction faster and more efficient but also expands the possibilities for architectural design, making 3DCP an essential innovation in the construction industry.

Building a 3D Printed Structure

To understand how an entire structure can be printed, it’s helpful to break down the process into four phases: Design, Preparation, Printing, and Post-Processing. We hope that this structured overview will provide a clearer understanding of the construction process using this innovative technology.

1. Design Phase: Time to design

Just like in traditional architecture, 3DCP construction begins with designing the structure in CAD software, yet with some specific design considerations to make the most out of the 3D printing technology. The most crucial one: Always keep your construction tool in mind as it defines vital parameters of your structure.

A good way to visualize the 3D construction printer is the COBOD configurator. For example, the size of the printer defines your printable area*, which sets the maximum dimensions for your finished structure. Similarly, the nozzle dimensions determine the wall thickness and should be considered from the very start when designing. 3DCP offers creative possibilities, enabling architects to explore innovative designs such as curved walls. At the same time, it is important to consider how to harmoniously integrate these modern elements with traditional components like windows, doors, and roofs. Blending these features is key to enhancing the aesthetics and functionality of the finished structure and the overall cost-efficiency of the project.

Expert’s advice: For optimal use of the technology, designing longer, continuous printing paths is beneficial as they are easier and more time-efficient to print compared to a series of shorter paths.

*Printable area = The area in which the printhead can move freely to print.

2. Preparation Phase: Getting ready to print

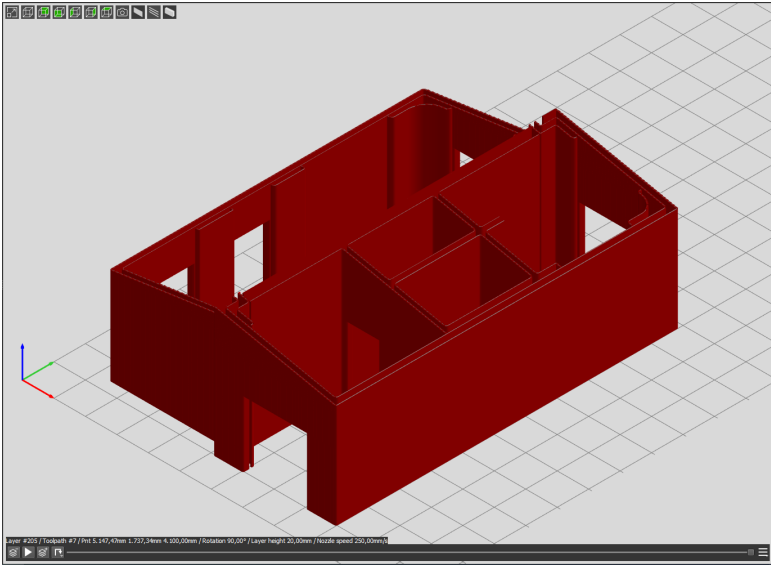

The preparation phase involves converting the CAD model into a 3D printable format using software, like for example, the COBOD Slice. This software, true to its name, slices the model into individual horizontal layers. However, the software can do more than that. It allows to set all the necessary printing parameters, for example, printing speed, layer height, or order of individual printable elements. By configuring these parameters, the 3D construction printer can operate autonomously and precisely during the printing phase.

3. Printing Phase: Bringing designs to life

Once the 3D construction printer and material delivery system are installed and set up, the printing process begins. The 3D construction printer can be operated by as little as four people: a printer operator, a materials operator, and two hands-on helpers. The printer operates autonomously, following pre-programmed parameters defined in the slicer and toolpaths, but the printer operator is tasked with digitally monitoring and controlling the process. Meanwhile, the materials operator focuses on continuously monitoring the material mix, making adjustments as needed to ensure the material maintains the proper consistency and quality throughout the printing process.

4. Post-Processing Phase: The finishing touches

The final step in the 3DCP process involves integrating traditional building elements, such as windows, doors, and electrical system into the newly printed structure. This phase blends conventional construction methods with innovative construction technology to finalize a functional space. While some aspects, like installing windows and doors, need to be completed post-printing, many elements, such as floor heating, can be incorporated during the printing process. This approach maximizes efficiency and ensures that the construction timeline is optimized.

Why use 3D Construction Printing?

Through the integration of innovative technology and conventional elements, 3DCP is redefining the possibilities within the construction industry. It is a process that not only pushes the limits of architectural design but also offers a new, more sustainable approach to building.

Design Flexibility

The technology’s three-axes gantry-based system allows architects to shift from conventional to more innovative architectural forms through three-dimensional printing. With the flexibility of the printhead, which can access any point within the printable area, even complex, wavy designs become not only possible but economically feasible. This capability not only broadens the scope of what is architecturally possible but also opens the door to cost-effective, yet visually striking building designs.

Speed

The use of a 3D construction printer significantly accelerates the construction timeline. A COBOD 3D construction printer can move at a speed up to 1000mm/s. However, the actual printing speed depends on factors like the design, choice of materials, the experience level of the operators, and local building and safety regulations. Therefore, while we typically suggest operating at a standard printing speed of 250 – 500mm/s, finding the right balance between these factors is key to efficient construction printing with a high-quality result.

Cost-Efficiency

3DCP not only refines the use of materials through material calculations and precise placement that ensures minimal waste, but it also redefines the traditional construction site setup. With just a few specialized staff members, including a printer operator and a materials operator, the entire printing process is managed efficiently and safely. This approach contrasts with the more labor-intensive requirements of conventional construction, reducing the need for a large onsite workforce. Additionally, the accelerated project timelines associated with 3DCP significantly shorten the overall duration of construction projects. These factors together promote both economic and operational efficiency, positioning 3DCP as a cost-effective alternative in conventional construction.

Sustainability

3DCP enhances sustainability in construction through multiple key approaches. First, its automated and precise construction techniques guarantee a responsible use of raw materials by ensuring only the necessary amounts are used, which substantially cuts down on waste. Second, this technology promotes sustainable design by ensuring stability and longevity of structures. Moreover, the faster construction timelines have positive environmental and public health impacts, notably by lowering emissions of particulates and reducing noise pollution. Together this helps to preserve natural resources but also improve the quality of life for people in and around construction sites.

Challenges & Future Outlook

3DCP, undoubtedly an innovative technology, is gradually being integrated into the construction industry. While its adoption brings numerous benefits, there are a few challenges to overcome. Skilled labor being one of the primary ones; operating our 3D construction printers, despite being straightforward, requires specialized training and skill development. To address this, we provide comprehensive training to ensure our customers are well-equipped to handle the technology. A second one is compliance with regional building codes. 3DCP is a safe and efficient construction method, but because it deviates from traditional techniques, it requires the formulation of new regulations and standards by local authorities. This adjustment process is ongoing, with gradual steps being taken toward integrating these innovations into standard building regulations.

Looking forward, we are optimistic about the role of automation and innovation in construction to achieve worldwide goals such as providing affordable housing and overcoming labor shortage in the industry. 3DCP not only promises to change how we build but also to continually evolve, becoming even smarter, more automated, and more efficient in the coming years.