Modern construction practices have become increasingly focused on sustainable building design. Using sustainable construction practices can reduce environmental impact, conserve natural resources, and contribute to long-term sustainability. With 3D construction printing (3DCP), sustainable building design can be approached in a new and innovative way.

This article explores the 4 most important principles of sustainable building design and how they are applied to 3D construction printing. Furthermore, we will discuss how this can improve the sustainability of the construction industry.

Sustainable Building Design Principles Applied in 3D Construction Printing

The following are some of the most important principles of sustainable building design that are applied in 3D construction printing:

1. Material and Waste Reduction

Due to the way materials are cut and shaped to fit specific building designs, traditional construction methods require a great amount of building material, as well as generate a significant amount of waste. Therefore, material and waste reduction is an important aspect to consider when designing sustainable buildings.

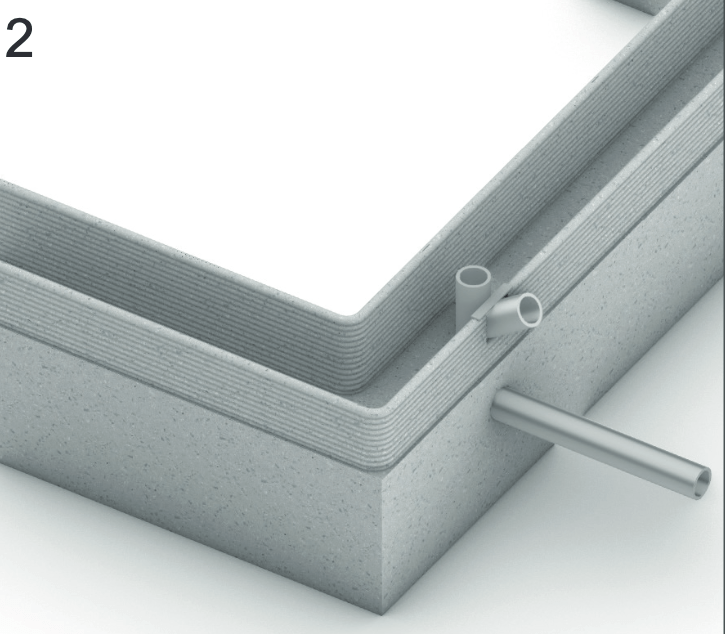

Using 3DCP, materials can be printed to exact specifications. For example, 3D concrete printing enables building components to be created efficiently, precisely, and accurately. This allows architects and builders to create complex shapes and curves that would be difficult or impossible to achieve with traditional construction methods. An advantage with complex geometries in house designs, is that it can utilize space more efficiently than traditional forms, and therefore reduce the amount of material needed for the construction.

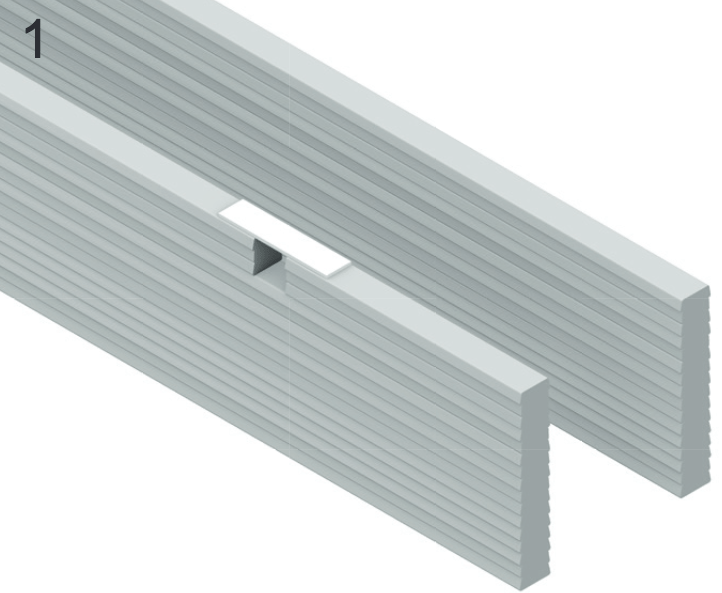

In addition, the need for cutting and shaping is eliminated with 3D construction printing, and thereby decreasing the amount of waste. Implementing wiring and plumbing showcases one of the best advantages of 3D printed houses. 3D printing method allows to create space for future wiring as it layers concrete during the wall printing phase. As a result, there is no need to drill or cut holes in the 3D printed walls to accommodate different installations, which facilitate the work for both architects and engineers, as well as reduce waste.

By utilizing these methods, construction companies can significantly reduce construction materials and waste, ultimately contributing to a more sustainable and efficient construction industry.

2. Sustainable Materials for 3D Printed Buildings

Other than reducing material and waste, one needs to consider if the construction materials are sustainable. Although concrete is a frequently used building material, its sustainability is a hotly contested issue. According to a Chatham House report (2018) , concrete is the most frequently used building material in the world, and it significantly contributes to climate change. Carbon dioxide emissions from the thermal and chemical combustion processes used to make cement are significant. Cement production accounts for more than 4 billion tonnes produced per year, or 8% of all CO2 emissions.

These insights naturally raise the question: is concrete sustainable? In short, concrete manufacturing has a large environmental effect. However, when done properly, it is possible to make concrete in a sustainable manner.

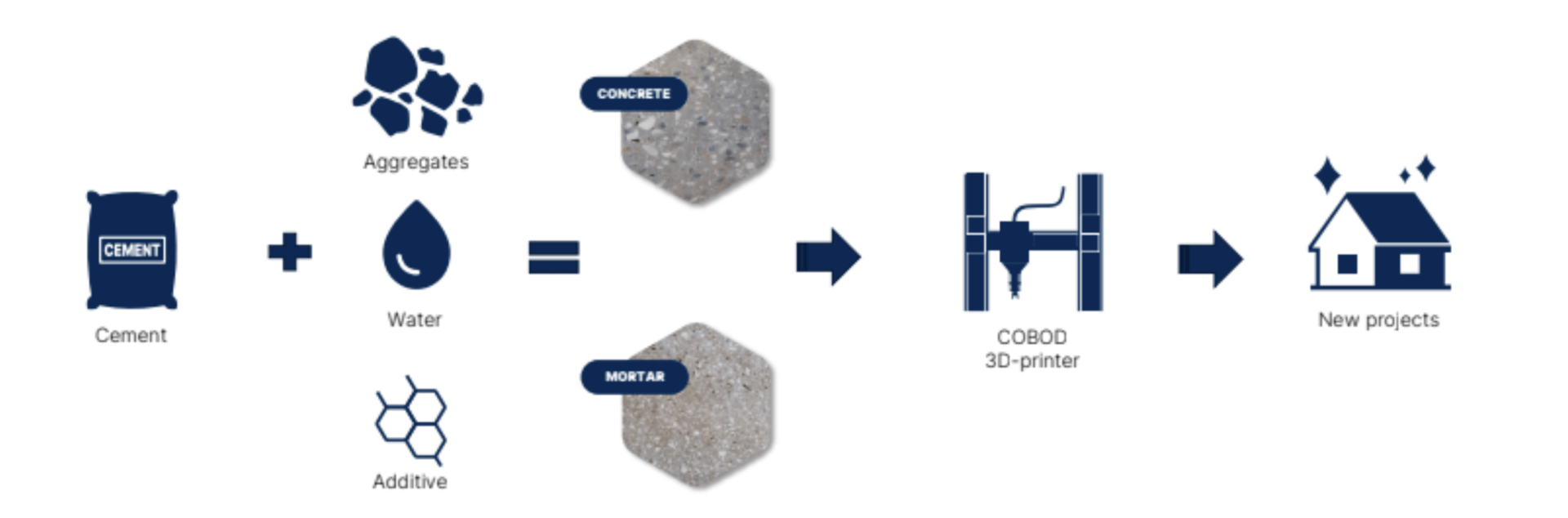

COBOD and CEMEX, the world leading concrete manufacturer, have joined forces to develop a groundbreaking new solution in the construction industry known as D.fab. This innovative solution combines COBOD’s 3D printing technology with CEMEX’s specialized concrete formulations to create durable and sustainable concrete structures.

D.fab admixture is a specialized additive that can be used in conjunction with 3D construction printing technology to enhance the properties of the printed material. It is a proprietary blend of chemicals that can modify the behavior of cement-based materials, making them more suitable for 3D printing.

The admixture is designed to improve the flowability and workability of the printing material, which can help reduce the risk of clogs or other printing defects. Additionally, it can improve the strength and durability of the printed object, which is essential for applications where structural integrity is critical.

The main advantage of this additive for 3D building methods is that to create the proper concrete mix, only 1% of D.fab is needed. Other materials, such as sand, gravel and water can be sourced locally. Therefore, carbon emissions from production and shipping might be decreased using 3D technology in the building sector. The amount of transportation emissions can be reduced by sourcing all materials locally and ordering only a small amount of D.fab for a project.

Another key benefit of using D.fab admixture is that it can be customized to suit the specific needs of a particular project. By adjusting the chemical composition of the admixture, it is possible to modify the properties of the printing material to achieve different levels of strength, durability, and other characteristics.

A more sustainable concrete solution can significantly reduce CO2 emissions, since it has such a great effect on one of the worlds most used materials. D.fab represents an exciting step forward in the construction industry, with the potential to revolutionize the way buildings are designed and constructed.

3. Improved Energy Efficiency

Another key principle of sustainable building design is energy efficiency. Designing 3D-printed structures with energy efficiency in mind is possible. With the help of technology, exact building designs that minimize energy waste and maximize energy efficiency are now possible. To ensure that every component fits exactly and creates an airtight building shell, 3D printing may be utilized, for instance, to construct building components with exact proportions.

To elaborate a bit more, 3D construction printing has the ability to produce building components with high accuracy and precision. This means that the parts produced can fit together perfectly, creating a more efficient and airtight building envelope. For example, 3D printing can be used to create custom-fitted insulation panels for walls, ceilings, and roofs that are designed to fit the exact dimensions of a building. This helps to minimize gaps and air leaks, which in turn reduces energy loss and lowers heating and cooling costs.

Another example is the use of 3D printing to create structural components such as columns, beams, and trusses. These components can be designed and printed to exact specifications, which allows for a more precise assembly process and reduces the amount of material waste generated during construction.

4. Optimization On Site

Sustainable building design principles go beyond just the design of the building itself – it extends to the practices and processes used on the construction site.

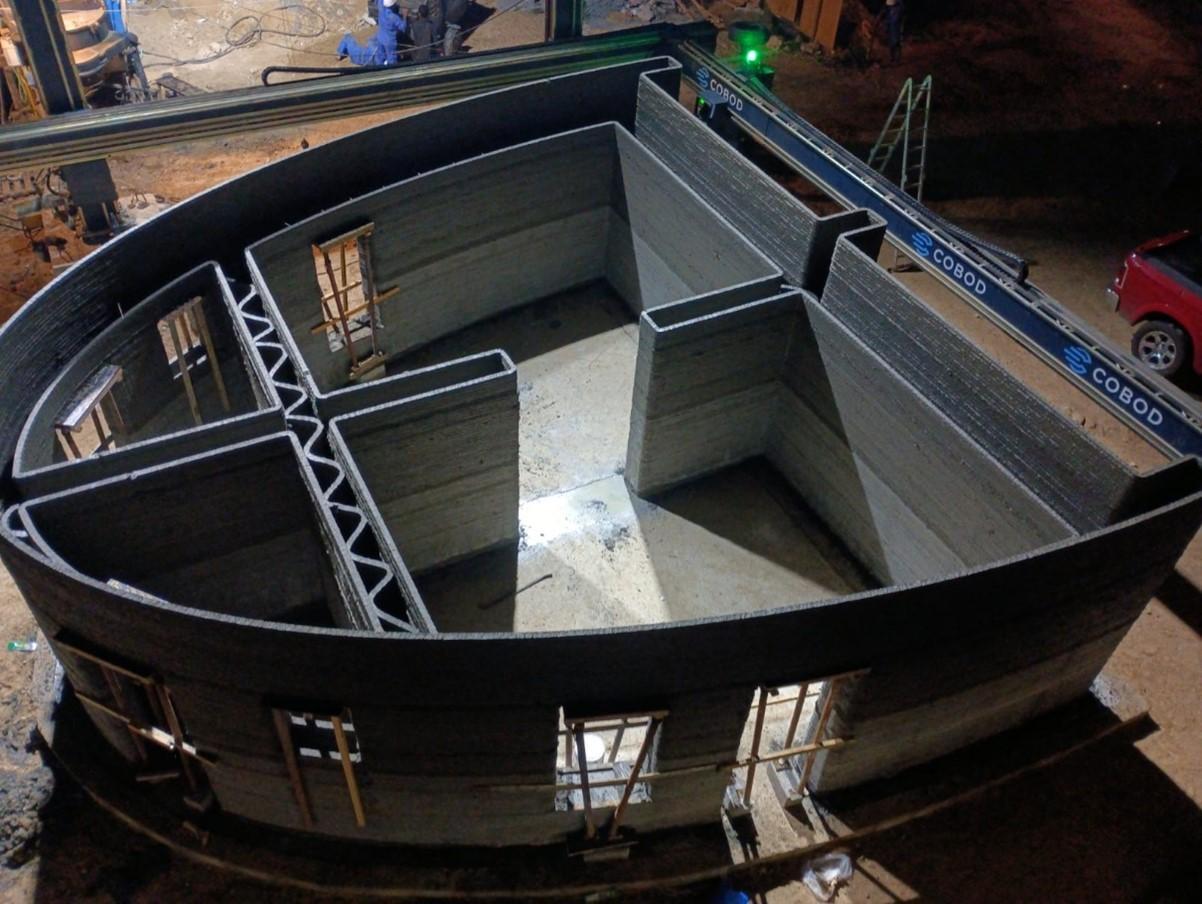

Traditional building techniques can take months or even years to finish, which causes lengthy periods of noise pollution, traffic congestion, and environmental impact. Construction time may be cut down greatly using 3D printing, minimizing its negative effects on the environment and nearby populations.

For example, GUTech Oman was able to 3D print 3 buildings in just 8 days using COBOD’s advanced 3D construction printing technology. The project demonstrates the incredible potential of 3D printing in revolutionizing the construction industry by significantly reducing construction time, costs, and environmental impact. This accomplishment marks a significant milestone for COBOD and the entire construction industry, showcasing the possibilities and advantages of adopting 3D printing technology in building design and construction.

How Can 3D Construction Printing Help the Environment?

Sustainable building design is becoming increasingly important in modern construction practices. By using 3D printing, it’s possible to create structures that are eco-friendly, energy-efficient, and long-lasting. 3DCP has the ability to completely transform the building sector by eliminating wasteful material use, lowering carbon emissions, increasing energy efficiency, and speeding up construction. We may anticipate seeing more ecologically friendly and sustainable building designs as technology advances.

COBOD’s innovative solutions offer a promising future for low-impact construction practices, and we can all contribute to a more sustainable world through the materials and practices we use in building design.Using cutting-edge 3D construction printing technology, COBOD is dedicated to enhancing the sustainability of the construction sector. Our printers are built with improved materials and include energy-saving features to lessen the negative effects of construction projects on the environment.