Over the years, 3D printing has evolved to become a mainstream technology with numerous industrial applications. From medicine to aerospace, 3D printing has made its way into almost every industry, bringing about new possibilities and revolutionizing the way things are made.

However, one industry that has particularly benefited from 3D printing is the construction industry. In this article, we explore the impact of 3D printing on various construction-related industries and how it is changing the future of building within these sectors.

Industrial Applications of 3D Printing Are Becoming Standard

3D printing is a versatile and revolutionary technology that has found its way into almost every industry. The method has evolved significantly over the years and is now becoming a standard in various industries. As a result, 3D printing is enabling manufacturers to produce parts and products in a more cost-effective, sustainable, and time-efficient manner.

As mentioned above, one industry is particularly benefiting from applying 3D printing – the construction industry. 3D printing in construction is changing the way we think about buildings, both residential and non-residential, as well as urban and habitable projects.

With the use of 3D concrete printing, it is now possible to construct buildings faster, cheaper, and more sustainable.

Let us look at a good example of how 3D printing is applied in the construction industry. GUtech managed to build 3 buildings with the utilization of COBOD’s 3D construction printer in just 8 days. The buildings were not only cheaper but also more environmentally friendly than traditional construction methods.

Moreover, even governmental authorities are now starting to recognize the opportunities of 3D printing in the building sector. After the completion of a 3D printed villa in the city of Riyadh, the Ministry of Housing in Saudi Arabia said: “In Saudi, we are rapidly developing in the construction sector through our Building Technology Initiative and implementing new technologies to enable 70% of the Saudi population to own their homes by 2030. Our strategy is to revolutionize the way people think about home through smart futuristic methods.”

Read more about pros and cons of 3DCP

3D Printing in the Construction Industry: Changing How We Build

3D construction printing (3DCP), also known as additive manufacturing (AM), allows for the production of complex shapes and designs that cannot be achieved using traditional construction methods. This technology has the potential to significantly reduce construction time and waste, while also enabling the use of sustainable materials.

Let us look at a few examples of how 3D printing is applied!

Examples of How 3D Printing is Applied in Various Industries

3D Printing for Urban and Habitable Projects

3D printing has become a valuable tool in the field of prototyping and manufacturing. The ability to rapidly produce a prototype or even a final product with high precision has revolutionized the traditional manufacturing process. With 3D printing, the design and production of a product can be accomplished in a fraction of the time and cost it would take using traditional methods.

In prototyping, 3D printing allows designers to create and test a variety of designs with ease. It is possible to quickly produce multiple prototypes, making it easier to experiment with different variations of a product. This means that product development can occur much more rapidly than before. This also allows for iterative design, where prototypes can be adjusted and reprinted based on feedback, allowing for rapid development and refinement of the product.

One other example of how 3DCP is being used for prototyping and manufacturing is in the creation of urban and habitable projects. Cementos Progreso, the largest cement company in Guatemala, is implementing COBOD’s state-of-the-art concrete printer for creating benches.

Typically, benches are made from wood, metal, or other traditional materials. However, using 3D printing technology allows for a more efficient and customizable approach to bench production.

Designers can create intricate and unique bench designs that would be difficult or impossible to create using traditional methods. Additionally, 3D printing allows for the creation of benches with complex internal structures that can increase durability and reduce weight.

Overall, the use of 3DCP for bench prototyping and manufacturing offers a range of benefits over traditional methods, from increased design flexibility to more efficient production and customization.

Application of 3D Printing in the Energy Industry

With 3DCP, it has become possible to build various applications in the energy industry. From wind turbine components to power plant parts, the technology is being utilized to create complex and intricate designs that were not possible with traditional building methods.

This innovative technique has the potential to transform the energy sector by enabling the production of customized, high-performance parts, reducing waste, and improving overall efficiency.

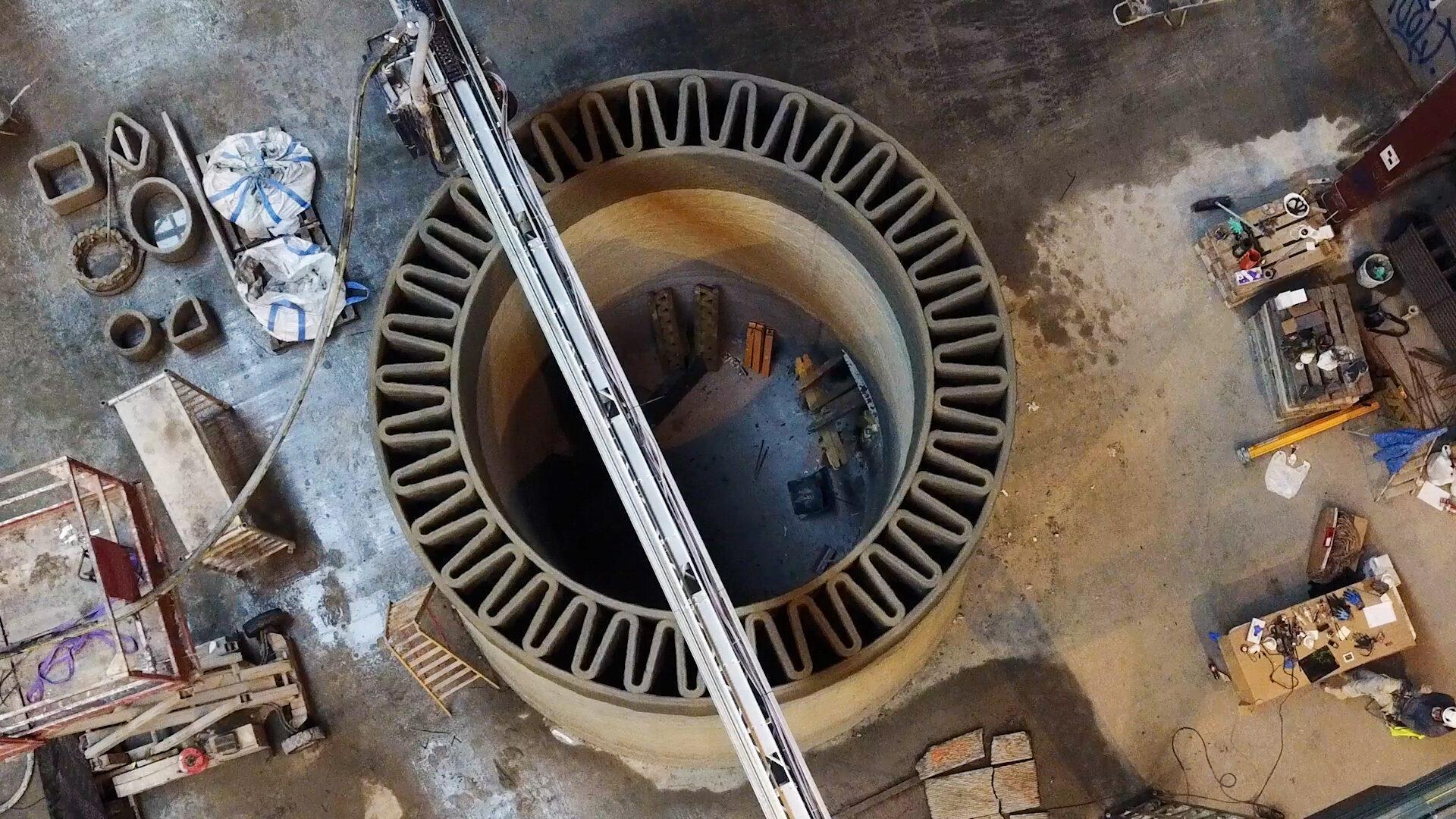

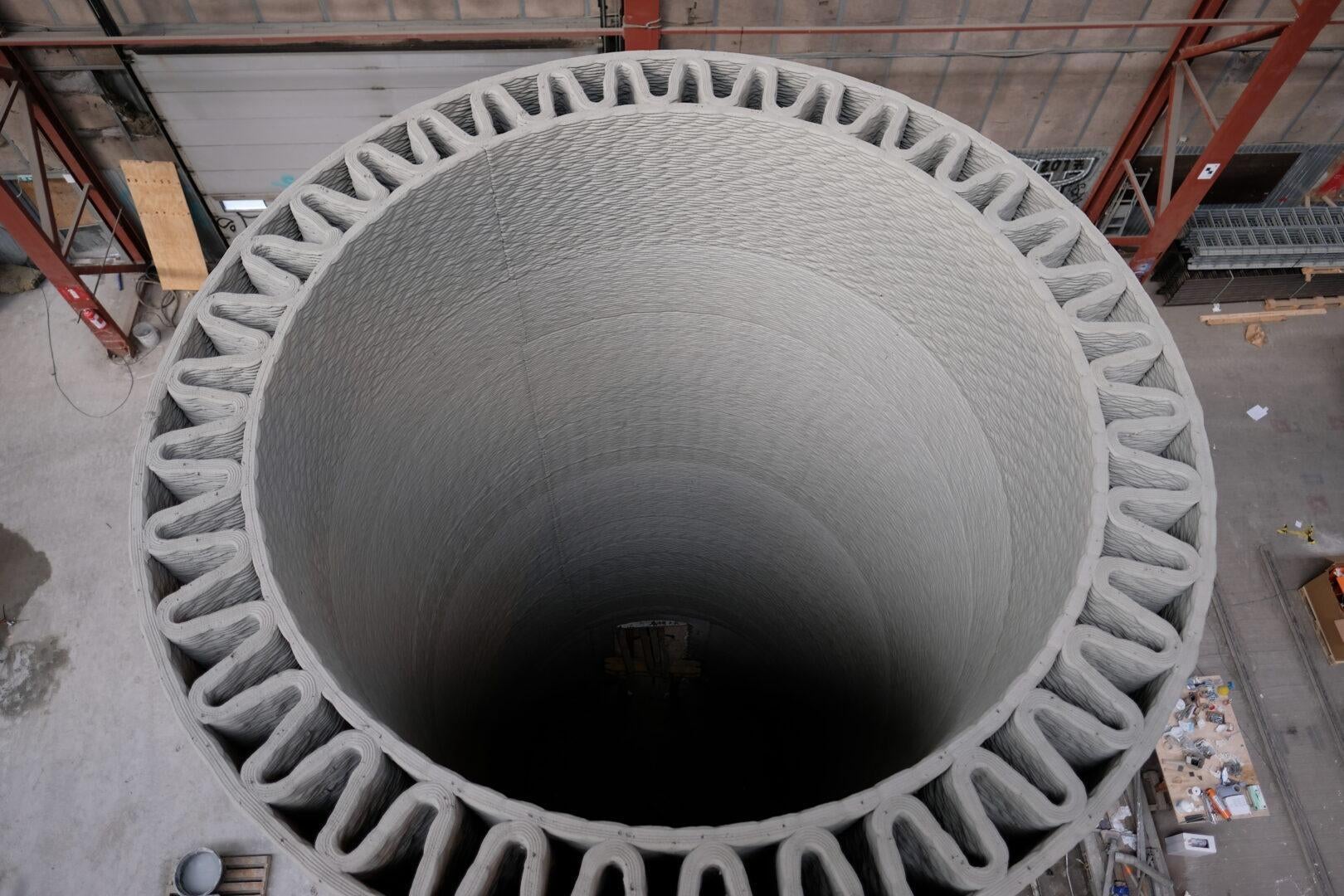

For example, GE Renewable Energy and COBOD are collaborating to develop 3D printed concrete bases for wind turbines, aimed at increasing renewable energy production, reducing the Levelized Cost of Energy (LCOE), and optimizing construction expenses. As part of the project, a wind turbine prototype featuring a printed pedestal was produced, along with a production-ready printer and range of materials for scaling up production.

In October 2019, a prototype of a tower pedestal measuring 10 meters in height was printed successfully in Copenhagen. Due to transportation limitations, the base of wind turbine towers cannot exceed 4.5 meters, which restricts the tower's height to under 100 meters. However, with the use of 3DCP, it is possible to print a tower base on-site and construct towers that are 150 to 200 meters tall. This innovative technique allows for the construction of larger wind turbines that can generate significantly more renewable energy.

Other Industrial Applications of 3D printing

As 3D construction printing technology continues to make advancements, its application in industrial sectors is also increasing. While it has already proven successful in the construction industry, there is now a growing interest in using this technology for other purposes.

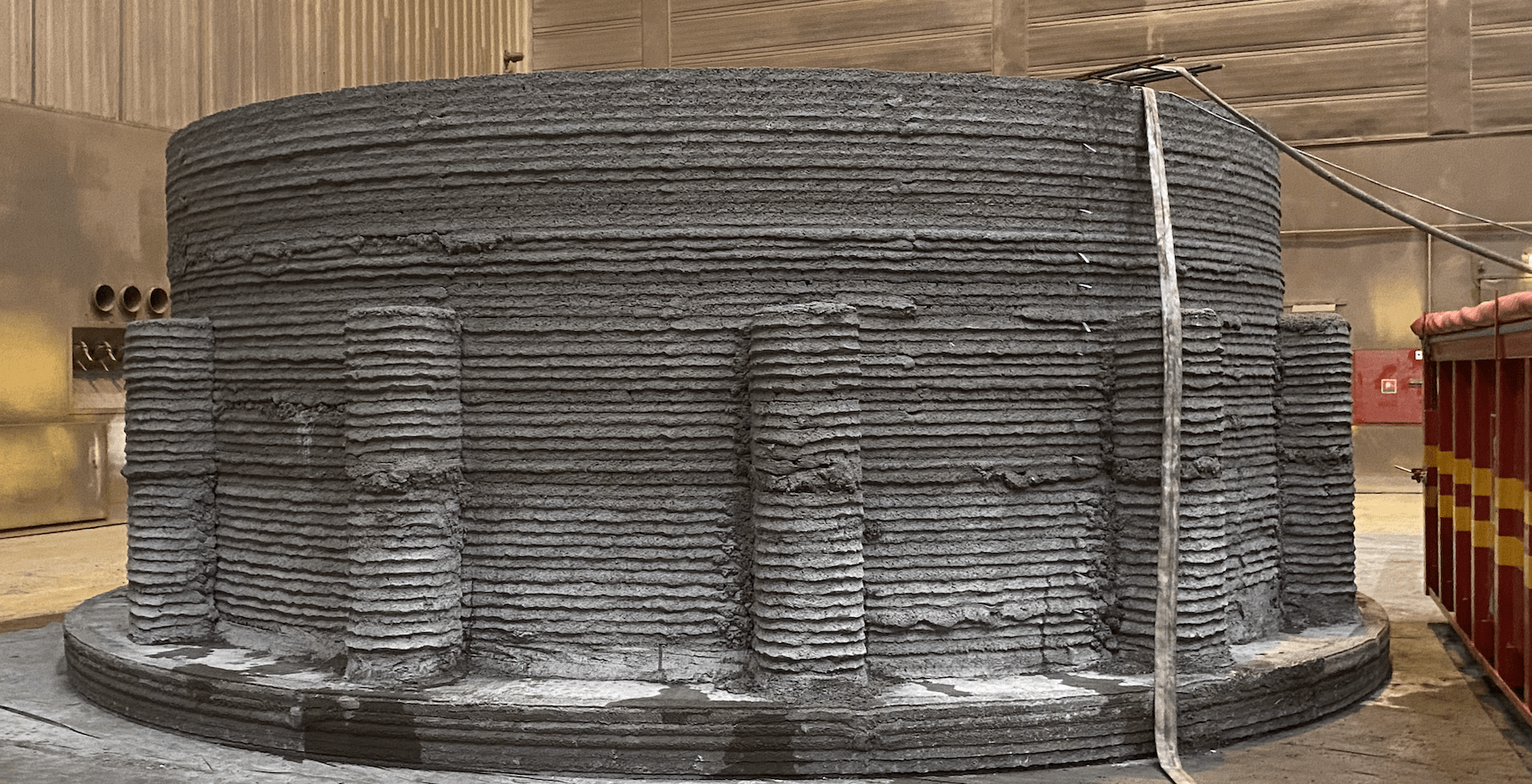

We are seeing a rise in global interest for printing tanks for biogas and water treatment facilities. The ability of 3D concrete printing technology to print on-site tall and wide concrete tanks is an appealing prospect for many. Not only can it be done economically and quickly, but it also optimizes the operational efficiency of these facilities.

This technology could revolutionize the manufacturing of these types of tanks, reducing production time and costs, and increasing overall efficiency. In addition to biogas and water tanks, there are likely to be many more industrial applications for 3D construction printing technology.

For example, it is also possible to utilize the 3D concrete printer for constructing:

- manholes

- dykes for oil and gas

- underground tanks

As research and development in this field continues to advance, we can expect to see more innovative uses of this technology in a range of different industries.

The Future of 3D Printing in Industrial Settings

3D printing is a technology that is revolutionizing many industries. From the construction industry to energy and beyond, 3D printing is making it possible to create products and buildings in ways that were previously not possible. As the technology continues to evolve, we can expect even more significant changes in the manufacturing landscape.

COBOD is known for its innovative 3D printing technology in construction, and we are excited to be a part of this revolution. We are at the forefront of 3D construction printing and our innovative technology allows for the construction of buildings using 3D printing technology. We have worked on numerous projects all around the world. Our technology is helping to change the way we build, making it faster, cheaper, and more sustainable.

As we expect the number of 3D printed buildings to double, or even triple, in 2023, we also expect the same for other applications. We hope more and more people from different industries recognize the innovative building technology. So, in the near future all of us can see 3D printed structures in every country, and even every city!